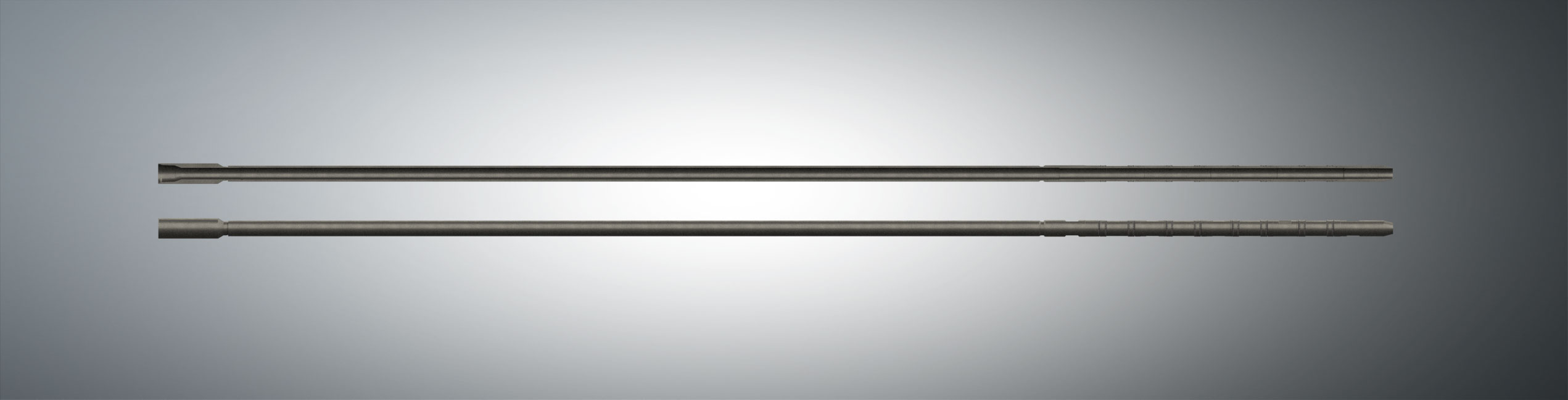

Seal Assembly (Stinger)

The Seal Assembly (Stinger) is made up and run with the inner production tubing string and seals in the seal bore receptacle of the flow crossover assembly, to provide a barrier between the inner and outer production tubing strings.

The stinger has a series of bonded seals providing 36” of seal movement. The seal assembly can either have a top or bottom no-go, or where a high load pump out prevention is required for injection / production systems, a snap latch can be used to prevent the stinger from unseating.

The UMS Flowell stinger assembly comprises of:

Features & Benefits

Specifications

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |